There are finally cost-effective solutions to replacing natural gas combustion for your facility

As the energy transition enables more and more renewable electricity on to the grid, facilities now have options to approach or beat the operating costs of steam or hot water generation from natural gas with industrial heat pumps and electric-thermal storage. Our consulting services can identify and help you implement these opportunities to aggressively drive down emissions and meet your net zero goals.

A systematic approach for your electrification process

Electrification projects are complex and require an expansive range of skills to support. Our consulting firm was built with a singular focus to meet this need with experience and a developed process.

Decarbonization Strategy

Our team will identify which facilities have the best opportunity for electrification, taking into account spark spread, wholesale market access, grid emission rate, load interconnection capacity, electricity tariffs, age of equipment, etc.

We then align the electrification proposition with your scope 1 and 2 strategies to identify benefits and opportunities to accelerate decarbonization. We can provide updates to existing strategies to take advantage of the new opportunities in this space.

We also provide energy efficiency and load reduction services to eliminate as much energy waste as possible to minimize the infrastructure requirements during the electrification process.

Technology

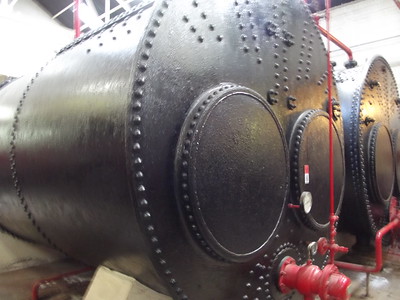

Historically, the only option to replace steam generation was an electric boiler, which had high operating costs and adding significant stress to the grid during peak times. Thankfully, this has now changed and our team can support identifying and procuring the right technology for your application.

Electric-thermal storage systems can charge an energy storage material with intermittent, low-cost renewable electricity and be discharged to generate steam throughout the day. In 2023 for ERCOT-North, using this type of system this would reduce electricity costs by 75% and avoid transmission charges compared to an electric boiler.

Industrial heat pumps can generate steam while having a COP of up to 2.0, reducing the required electrical infrastructure and enabling cost parity even with higher electricity costs.

For facilities without high-temperature loads and limited downstream steam infrastructure, hot water heat pumps will likely be the most efficient electrification pathway. Heat recovery chillers can recover otherwise wasted heat to provide heat during periods of simultaneous heating and cooling.

Electricity Supply

The value proposition of these new technologies is driven on pushing electricity prices down to parity with natural gas operating costs. Our team will identify methods for receiving the lowest cost renewable electricity possible.

Typically, the best method is to access the realtime wholesale electricity market through a energy supplier or as a wholesale market participant. We prioritize facilities where this is achievable, but can also work through existing utility relationships.

Sourcing renewable electricity and strong claims is also critical. Our team has significant experience in sourcing and negotiating virtual power purchase agreements (multiple VPPAs in ERCOT, SPP, and AESO), as well as onsite renewable electricity generation.

Focus Areas

Our consulting practice focuses on target facilities: universities, large campuses, and industrial facilities.

University campuses are often heated with legacy CHP steam plants. Steam generated in these plants is often distributed throughout the campus in order to heat individual buildings.

Replacing steam in these campuses with hot water, as is commonly done to meet scope 1 goals, requires a complete overhaul of not only the central plant equipment, but often the distribution and downstream heating infrastructure.

Decarbonizing the steam production reduces the need for downstream infrastructure changes, enabling faster decarbonization at a much lower capital cost.

Large campuses, such as hospitals and centralized health care campuses, often utilize steam for heating their facilities as well. For facilities where changing to hot water would require significant changes to downstream infrastructure, utilizing decarbonized steam-generating equipment may be the easiest pathway to reducing scope 1.

In cases where steam is not directly used, hot water heat pumps may provide a more efficient solution. We focus on identifying the most attractive pathway for decarbonization, evaluating capex, opex, timing, and operational considerations.

Industrial facilities generate 23% of the US greenhouse gas emissions and 68% of industrial energy use is for process heating. Industrial facilities are one of our prime target areas as they often have low electricity prices and high usage, enabling projects to have large impacts and attractive ROIs.

Our team has significant experience in industrial and manufacturing facilities, recognizing the challenges of implementing energy projects in 24/7 facilities where downtime represents real costs. Our focus on steam generating equipment reduces the need for downstream changes, reducing or eliminating additional downtime required for implementation.

Reach your net zero goals!

Connect with us today to support your net zero journey.